Factory Direct Pricing | Bulk Orders Available

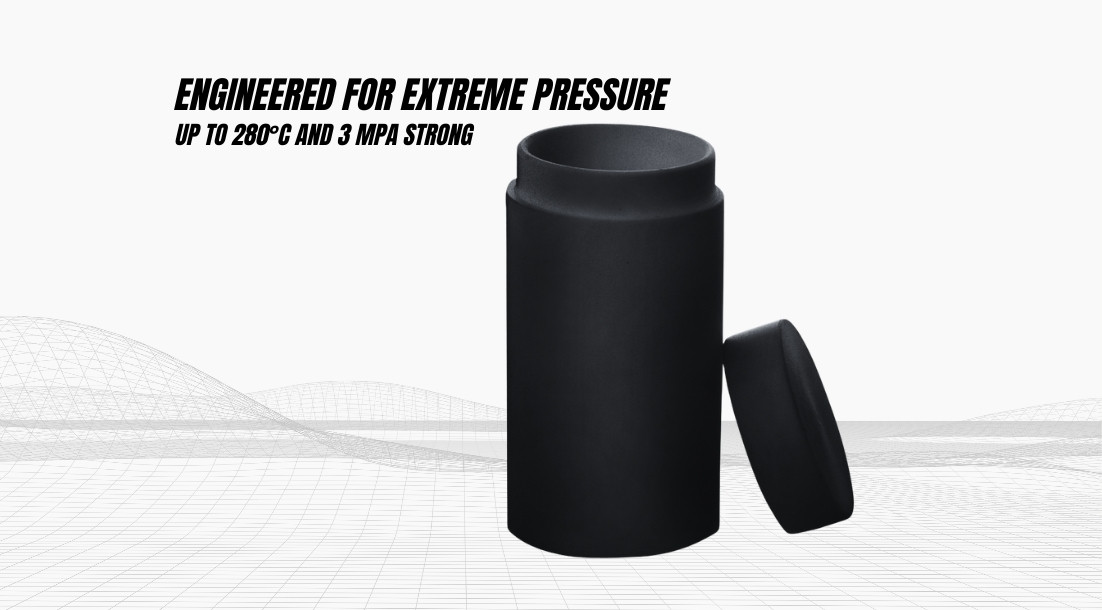

The PPL-lined hydrothermal autoclave is manufactured mainly by two components; (PPL inner vessel) and stainless steel (SS-316) outer shell. PPL is an abbreviation for polypropiolactone, a semi-crystalline aliphatic polyester derived from plants. Polyphenylene polymers, known colloquially as polybenzenes or polyphenyl, are used as liners in high-temperature autoclaves. PPL is a kind of polymer with distinctive chemical structures. After simultaneous curing, the resin is very stiff and robust, displaying outstanding mechanical capabilities and chemical resistance at temperatures approaching 280 ºC.

We produced this autoclave from the range of 25ml to 500ml volume capacity. The PPL inner vessel is resistant to corrosion, acidic and alkaline solutions. If the researcher needs better temperature stability, it is better to prefer this reactor over a Teflon-lined reactor.

The PPL lined hydrothermal autoclave is costly as compared to Teflon lined autoclave. Temperature and color are two significant properties in the PPL vessel camber that distinguishes it from the Teflon vessel. The PPL lined reactor is black and has a higher temperature resistance. The reactor setup's maximum operating temperature for the continuous reaction is 280 °C. The safe temperature for the complete setup is 260 °C. Researchers should keep the temperature within the safe temperature range. The maximum design pressure is 3Mpa.

The PPL lined hydrothermal autoclave is suitable for smaller volumes. The outer SS body contains two caps; one is primary, and another is secondary. The secondary cap is smaller, placed at the top of the reactor, and extremely important to press the liner into the outer shell.

The PPL-lined hydrothermal synthesis autoclave reactor is a closed container used to dissolve refractory material. It mainly applies in preparing the samples for atomic absorption spectrometry and plasma emission examination, among other things. It is appropriate for small-dose synthetic reactions that need quick dissolution of refractory material in a high-temperature, high-pressure, airtight environment. It is utilized to prepare samples in the gas phase, liquid phase, plasma mass spectrometry, atomic absorption, atomic fluorescence spectrum, and chemical analysis technique. Its applications lie in the digestion of lead, copper, cadmium, zinc, calcium, manganese, iron, mercury, and other heavy metals.

Nanotechnology is one of the driving factors that can change material science in the modern era by advanced sciences. Hydrothermal synthesis is an advanced technique for manufacturing functional nonmaterial from transition-metal compounds. It can withstand high pressure and temperature for an extended period, which provides an ambient environment for nonmaterial production. In various situations, self-organized hierarchical nanostructures such as nanoflowers and nanourchins can emerge spontaneously. The hydrothermal approach is rapidly being used to synthesize nanoparticles by enterprises and R&D institutes worldwide.

| PPL Lined Hydrothermal Autoclave — Specifications | |

|---|---|

| Product Name | PPL Lined Hydrothermal Autoclave Reactor |

| Inner Liner Material | Polyphenylene Polymer (PPL) |

| Outer Body Material | Stainless Steel (SS-316 Grade) |

| Available Volumes | 25 mL, 50 mL, 100 mL, 150 mL, 200 mL, 250 mL, 500 mL |

| Safe Operating Temperature | Up to 260°C |

| Maximum Operating Temperature | Up to 280°C |

| Maximum Working Pressure | 3 MPa (30 bar) |

| Heating / Cooling Rate | ≤ 5°C per minute |

| Sealing Type | Threaded / Screw Cap Type |

| Chemical Resistance | Excellent resistance to acids, alkalis, and solvents |

| Applications | Hydrothermal synthesis, nanomaterials, crystal growth, high-pressure chemical reactions |

| Usage | Laboratory research and industrial R&D applications |

Place the sterilizing materials, and PPL lined hydrothermal autoclave on a clean surface. Rotate the SS rod anticlockwise and twist the screw-type threaded primary SS cap (SS Alloy 316) until it is open. There are two types of SS disc in the reactor: one on the bottom and one on top of the vessel chamber. Lift the top SS disc or cover to remove the black color PPL-lined reaction chamber. Fill and shut the reaction chamber with solvent. Make sure to seal the vessel cap to avoid pressure leaking. Place a liner in a stainless steel chamber. Keep the top disc over the vessel in place, and ensure that the vessel is in position in the stainless steel chamber. Then, rotate the primary SS cap clockwise until it no longer rotates. Finally, the SS rod of the secondary cap tightens and places the reactor inside the oven.

We at Shilpa Enterprises, we sell quality products all over the world. We provide PPL lined hydrothermal autoclave with an ultra-high performance, which is helpful in the oil and gas sector for harsh HP/HT conditions. It can withstand lengthy exposures and has outstanding chemical and creep resistance at that temperature. Therefore, as per the client's design and quantity, we customize the hydrothermal reactor set-up in a larger size with effortless ease. Moreover, our products are the most affordable and reasonable in the market. Send us a direct message or call us from the information on the contact us page for the bulk requirement.