| Parameter | Typical Value | Alternate / Custom Range |

|---|---|---|

| Substrate material | Soda-lime glass / Borosilicate (as per order) | Custom glass types on request |

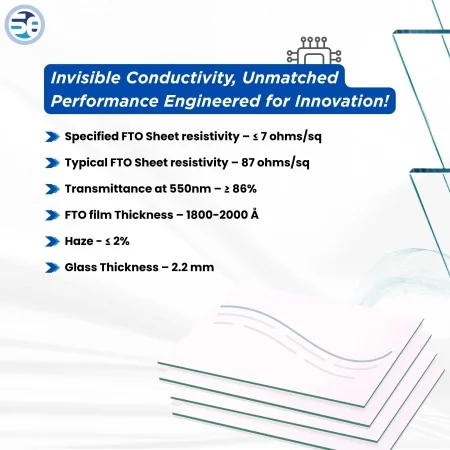

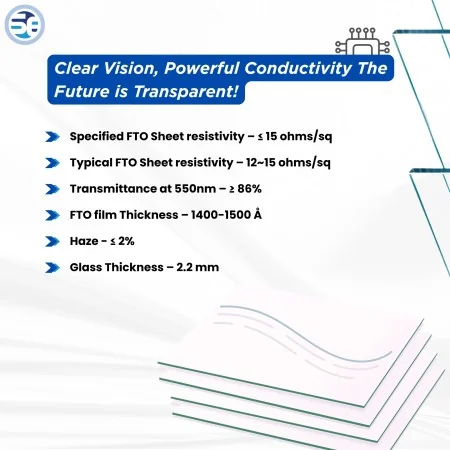

| Sheet resistance (Ω/□) | ~ 7 – 15 Ω/sq | Custom (e.g. 5 – 20 Ω/sq) |

| Optical transmittance | > 82 % @ 550 nm | > 80 % typical in visible range |

| Coating thickness | ~ 200 – 400 nm | Custom thickness by design |

| Max operating temperature | ≈ 550 °C | Up to 600 °C under special glass |

| Glass thickness | 0.7 mm / 1.1 mm / 2.2 mm standard | Other thicknesses available on request |

FTO coated glass (fluorine-doped tin oxide coated glass) is a form of TCO (transparent conducting oxide) conductive material that provides less expensive conductive glass than ITO-coated glass. It is a functional conductive glass product covered with a transparent FTO conductive oxide layer via a physical or chemical bonding method. The FTO coated glass substrate is coated on one side and insulated on the other. This coating is resistant to higher temperatures. It is weather-resistant and thermally stable, resulting in low sheet resistance and high transmission ability.

The highest operational temperature is 450 degrees Celsius. The glass thicknesses employed for the FTO coating are 1.6mm, 2.2mm, and 3.2mm. It has surface resistances of less than 7 ohms, 10 ohms, and 15 ohms. It has been utilized for solar cell research and development, which is less expensive than ITO-coated glass. It is single-sided coated glass with a tetragonal structure and flawless symmetry.

Due to its superior high-temperature endurance, FTO conductive glass has recently emerged as the ideal transparent electrode material for perovskite solar cells. The product provides an environmentally friendly coating method that dramatically decreases material usage, leaves a finer and more uniform coating without leaking, and reduces maintenance significantly. It may give outstanding anti-reflection properties to glass when coated with a very thin, homogeneous, and durable layer while decreasing exhaust gas and energy consumption during the deposition, and the drying time is quick.

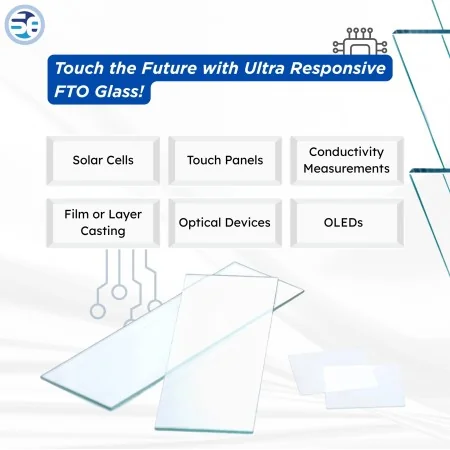

FTO glass (Fluorine-doped Tin Oxide) is a translucent conductive metal oxide used to make transparent electrodes for thin film photovoltaics. It is also used in organic photovoltaics, silicon cells, cadmium telluride, decolorization solar cells, and hybrid perovskites. FTO glass has various qualities that make it excellent for manufacturing a wide range of optoelectronic devices, including low surface resistance, high optical transmission, scratch and abrasion resistance, thermal stability up to high temperatures, and chemical inertness. Other applications for FTO glass include:

The following items are required for etching.

FTO glass, etch-resistant tape, zinc powder, hydrochloric acid, cotton bud, and a multimeter. The procedure for etching FTO coatings is outlined below.

The following items are required for cleaning the FTO coated glass after etching: FTO slides, substrate rack, isopropyl alcohol, and UV Ozone Cleaner. A step-by-step approach to cleaning the conductive substrate is provided below.

Q: What is the typical sheet resistance of FTO coated glass?

A: Our standard range is ~7 to 15 Ω/square, with options for lower or higher values based on design requests.

Q: Can I get patterned FTO coatings (e.g. via etching)?

A: Yes — we support custom pattern etching services. Provide your mask or design when ordering.

Q: Is FTO better than ITO for high-temperature applications?

A: Yes. FTO is more thermally stable at elevated temperatures and is often chosen for high-temperature processing environments, whereas ITO may degrade under such conditions.

Q: What is the maximum operating temperature?

A: The recommended maximum is ~550 °C (due to glass substrate limitations), though under specific conditions, some FTO films may withstand slightly higher temperatures.

Shilpa Enterprises is renowned for providing high-quality service at reasonable prices. Our workforce is among the best on the market, with over 10 years of experience in the chemical business. Our FTO coated glass slide has excellent temperature resistance, and we can tailor the size and etching pattern to your specifications. We offer product modification on demand to satisfy the needs of our customers. We are adept at fulfilling worldwide quality standards because we have a dedicated QA team. We accept both bulk and individual orders. Clients can get product advice and support from our professionals 24 hours a day, seven days a week. Working with us ensures your complete happiness. Our products are packed with shockproof packaging of type 4 layers and can be shipped to any area worldwide. Contact us via our contact page to place orders or learn more about our products.